Vorsteiner Wheels

Vorsteiner Flow Forged V-FF 104 Wheels

Additional Info

Engineered to Perfection

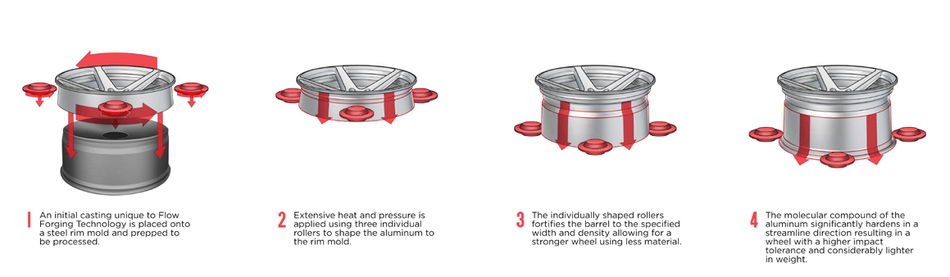

Vorsteiner Flow Forged Technology is on average 25% lighter compared to a conventional cast construction, yet substantially stronger. The majority of surplus weight can be shaved by the use of less but stronger aluminum. In addition, they meticulously reduce the weight of the wheel utilizing back-pad pocketing as well as front and rear spoke pocketing.

Vorsteiner engineers effectively study all their vehicle applications to ensure that the installation is as effortless as possible. All factory components including upgraded brakes, TPMS sensors and lug bolts can be reused for a plug & play application. No spacers, hub-centric rings or aftermarket lugs are required.

Function and Form

A wheel can be attractive and lightweight because it uses equal raw materials and manufacturing equipment, however, design strength is another objective on its own. Vorsteiner thoroughly study each individual shape and arrangement to ensure their unique architecture has the longevity to outlast the most severe conditions.

- Lightweight Design

- Engineered lug seats manufactured to work with OE hardware

- Stepped & tapered spoke design to maximize strength while accentuating slender spokes

- Performance front face pocketing adds a unique design element as well as weight savings

- Full face spoke design extends each spoke to the rim, creating a visually larger appearance

Flow Forging Process